Conveyor Belts, Power Transmission Belt and Silent Gears

Pebax® Elastomers Offer Outstanding Energy Return for Optimal Power Transmission

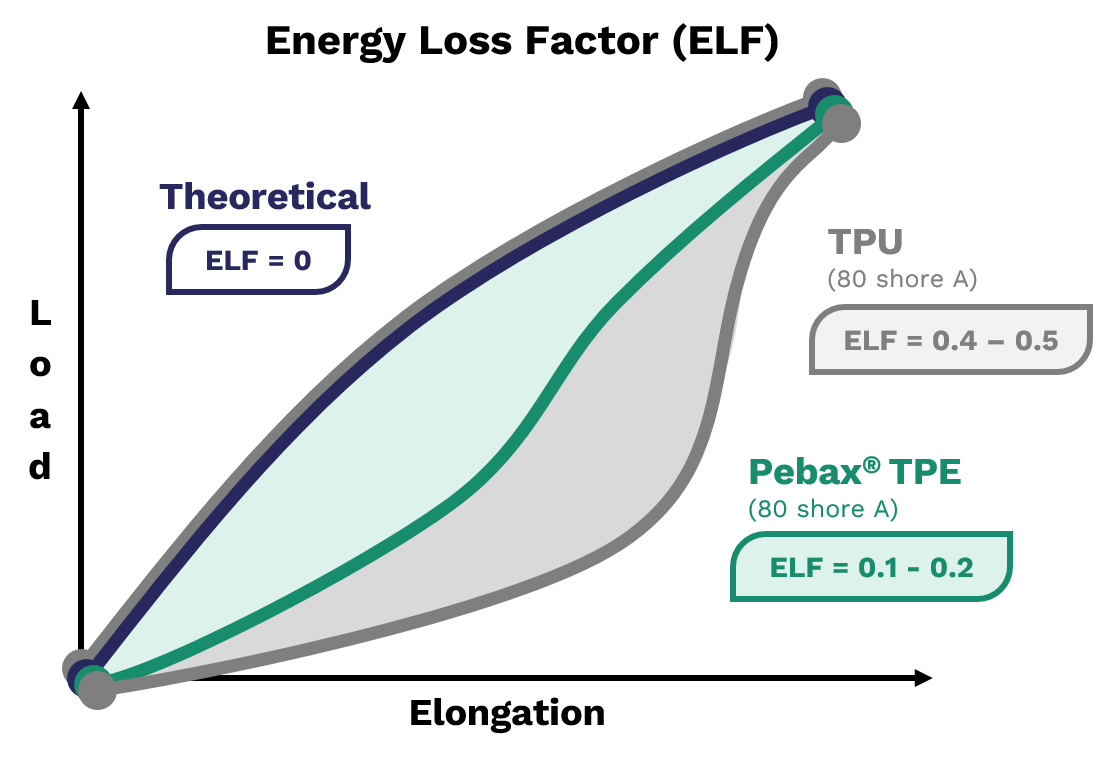

Hysteresis is defined as the energy lost during a cyclic mechanical stress of a material and is a function of the modulus and the loss factor, tan ∂.

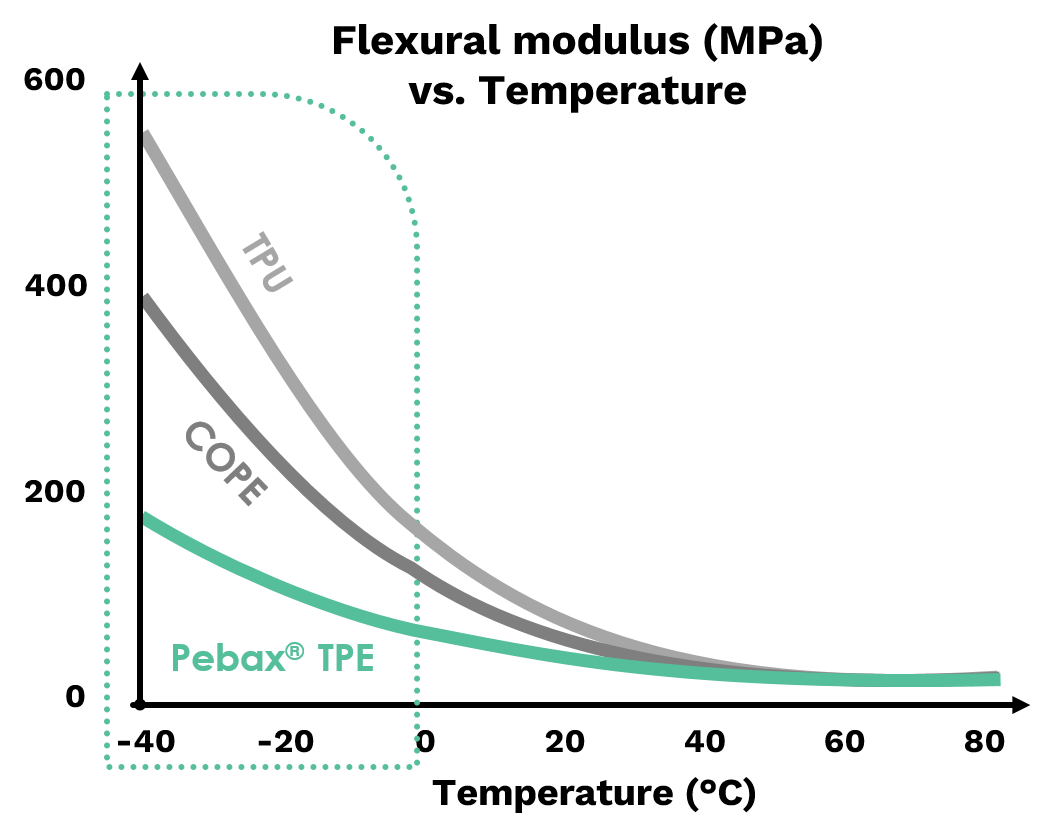

The tailored molecular microstructure of Pebax® resins contributes to lower hysteresis and tan ∂ when compared to other commonly used thermoplastic elastomers. The combination of this property (over a wide temperature range) as well as tremendous toughness, light weight and ease of processability make Pebax® resins powerful candidates for highly efficient power transmission belts.

Monolithic conveyor belts Pebax® Elastomer

Monolithic conveyor belts are made from a single material and are often used in manufacturing industries such as textile, food (meat, fruits, vegetables), wood, and more. A single large continuous piece of Pebax® material can be used for a high-performance mono-material conveyor belt. Pebax® elastomers cover a wide range of hardness and show high reliability in terms of energy loss, temperature resistance, wear and tear resistance and anti-static properties.

Power transmission belts with Pebax® Elastomer

A synchronous belt or timing belt, is a type of power transmission belt that is used to transfer rotational motion between two or more shafts in machinery and mechanical systems. Power transmission belts have usually a composite structure in which Pebax® Elastomers are the intermediate layer highly compatible with the fabric and the rubber layers. Pebax® Elastomers are the material of choice for multi-material power transmission belts thanks to their excellent processability, weldability, lightness (adapted for high speed) and low noise and vibrations.

Flexural modulus (MPa) vs. Temperature

Energy Loss Factor (ELF)

Pebax® Elastomers in Power Transmission Belts

| Pebax® Elastomers Main Properties | Applications | Pebax® Solutions | |

| Low hysteresis | Low energy dissipated and heat build-up High level of power transmitted |

Belting | Pebax® 33 series: 25 to 55 ShD grades |

| Excellent flex fatigue and resistance | Low relaxation | Belting | Pebax® 33 series: 40 to 70 ShD grades |

| Creep resistance | Pebax® 33 series: 25 to 55 ShD grades | ||

| Low vibration and noise Low density |

Belting | Pebax® 33 series | |

| Ease of processing | Easy and strong splicing | Belting | Pebax® 33 series |

| Chemical resistance | Belting | Pebax® 33 series: 40 to 70 ShD grades | |

Looking for technical data?

Search for technical data sheets and even compare grades side-by-side